Customer ❤️

Click to see what our customers have to say

At home

Grow food for yourself, your family, and your community by installing FarmBot on a raised bed, urban rooftop, or in a small greenhouse at home.

Enjoy the freedom of food sovereignty and knowing things are taken care of when heading out of town. Fully automated, hyper-local food production has never been so attainable.

The Sudweeks Family

Cedar City, Utah

Garrett and Lexie Sudweeks are first generation FarmBot builders passionate about sustainability. Watch them put together their v1.2 FarmBot Genesis kit and hear what it means to them to grow their own food and be a part of the larger open-source FarmBot community.

Watch the video ↑

Inspiring the next generation

K-12 schools and universities, everywhere

FarmBot is a practical, engaging, and most importantly: FUN hands-on tool for learning robotics, nutrition, soil science, biology, coding, and a myriad of other STEM learning objectives.

See the film ↑

In class

Over 500 educational institutions have purchased FarmBot kits to engage and inspire the next generation of farmers, engineers, plant scientists, and coders.

By tapping into our global community of schools, universities, DIYers, and professionals, your students will gain first hand experience working in a 21st century collaborative development workflow. Join us and bring this cutting-edge STEM-based learning and research experience to your students.

More Applications

FarmBot for Accessibility

Thrive Upstate is a non-profit in Greenville, South Carolina that provides people with disabilities services, opportunities, and support, so they may thrive. See how they use FarmBot for horticultural therapy and to empower individuals who otherwise could not grow their own food.

Play the story ↑

Growing Food in Space

In 2017, FarmBot and other open-source food groups were invited to NASA to brainstorm open-source approaches to food production. See how FarmBot and our community of open-source contributors are helping humanity grow food in space, on the Moon, and Mars.

Watch the documentary ↑

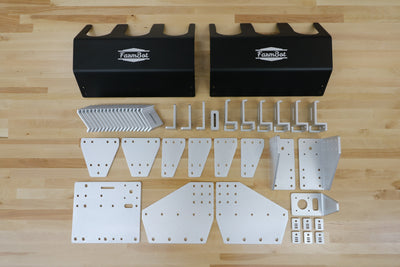

Premium Hardware

We've gone to great lengths to design, manufacture, and source only the highest quality components for our kits.

And because everything is made from aluminum, stainless steel, and UV resistant ABS, FarmBot will last for years in outdoor environments.

Designed from the ground up

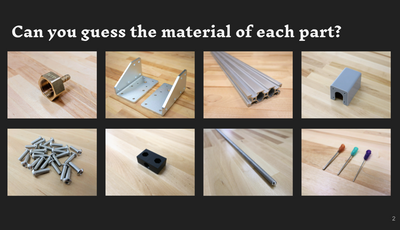

Drivetrain

All FarmBots are powered by four powerful NEMA 17 stepper motors, GT2 timing belts and pulleys, and a stainless steel precision leadscrew.

Electronics

Our custom electronics feature TMC2130 stepper drivers with built-in stall detection and Raspberry Pi computers for web connectivity.

Plates and Brackets

Stamped and machined out of 6061 aluminum, our plates are tumble polished, sandblasted, and anodized to achieve a premium aesthetic.

What you can grow

FarmBot is well suited to growing a polycrop of many common garden veggies at the same time. Crops we've had success with include Bok Choy, Lettuces, Radish, Beets, Chard, Arugula, Broccoli, and much more.

By placing vining and other indeterminate crops near the ends of the bed and training them outwards, you can easily double or triple the area your plants can utilize while still being maintained by the FarmBot.

Both FarmBot Express and Genesis can grow all of the veggies needed by one person, continuously, for less cost after 2 years than shopping at the average US grocery store. Our XL bots can serve a family of four with an ROI period as short as 1 year.

Which FarmBot is right for you?

FarmBot Genesis

Genesis models offer enhanced capabilities, service larger areas, and have a greater ability to be customized and upgraded. They are designed for prosumers and enthusiasts willing to pay a little more to have every feature and capability at their disposal.

FarmBot Express

Choose Express XL if you want to get your FarmBot set up as quickly as possible and only need it to do the basics. Express XL has been designed for the everyday user and efforts have been made to make these bots as affordable as possible.

All kits ship FREE worldwide

Not ready to order just yet?

Subscribe to our email newsletter instead

Tech Specs

| NEW! | NEW! | ||

Genesis v1.7 |

Genesis XL v1.7 |

Express XL v1.1 |

|

|

Max machine area (service area will be slightly less) |

1.5m x 3m (4.5m2) 5ft x 10ft (50ft2) |

3m x 6m (18m2) 10ft x 20ft (200ft2) |

2.4m x 6m (14.4m2) 8ft x 20ft (160ft2) |

| Max machine height |

1.5m

5ft |

||

| Max plant height |

0.5m

1.5ft |

||

| Raised bed interface |

NEW!Custom aluminum extrusion tracks

|

Rolls directly on wood |

|

| Percent pre-assembled | |||

| Time to assemble | 5x FASTER!3 hours | 5x FASTER!4 hours |

1 hour

|

| Extrusions | Silver anodized aluminum |

||

| Plates | Silver anodized aluminum |

||

| Plastic parts | UV stabilized gray ABS |

||

| Hardware |

Stainless steel and aluminum

|

||

| Tool head | Universal tool mount |

3-in-1 tool head |

|

| Interchangeable tooling | ✅ |

❌ |

|

| Automatic tool changing | ✅ |

❌ |

|

| Custom tool support | ✅ |

❌ |

|

| Seeder | Yes, as interchangeable tool |

Integrated into tool head |

|

| Watering nozzle | Yes, as interchangeable tool |

Integrated into tool head |

|

| Weeding | Yes, via rotary tool |

Integrated into tool head |

|

| Rotary toolNEW! |

Yes, as interchangeable tool

|

❌ |

|

| Soil moisture sensor |

Yes, as interchangeable tool

|

❌ |

|

|

Soil temperature sensor (software support coming soon) |

Included with moisture sensor

|

❌ |

|

| Camera | IP67 rainproof USB Camera |

||

| Seed containers |

2x seed troughs and holder

1x seed tray 1x seed bin |

2x seed troughs and holder |

|

| Toolbays |

2x 3-slot toolbays

|

❌

|

|

| Computer | Raspberry Pi 4B |

Raspberry Pi Zero 2 W |

|

| CPU speed | 1.5GHz quad-core |

1GHz quad-core |

|

| RAM | 1 GB |

512 MB |

|

| Real-time clock | Yes |

||

| Microcontroller | Farmduino v1.6 |

Farmduino Express v1.1 |

|

| Stepper drivers | 5x TMC2130 integrated chips |

4x TMC2130 integrated chips |

|

| Motors | 4x NEMA 17 stepper motors |

||

| Rotary encoders | ✅ |

❌ |

|

| Closed-loop positioning | Yes, via encoders |

❌ |

|

| Stall detection | Yes, via encoders |

Yes, via driver chips |

|

| Solenoid valve | 24V, normally closed |

||

| VacuumUPGRADED | 24V with EMI filter |

||

| LED light strip |

1.5m 5ft |

3m 10ft |

2.4m 8ft |

| Extra peripheral plugs | 2x extra plugs |

None |

|

| LED indicators |

Sync

Connection 2x user customizable |

None |

|

| Push buttons |

E-stop

Unlock 3x user customizable |

E-stop |

|

| WiFi | Yes |

||

| Ethernet | Yes |

||

| Power supply | 100W, IP67 waterproof |

||

| Input voltage |

110 to 220V AC

|

||

|

Shipping dimensions (main carton) |

22cm x 42cm x 106cm

9 in x 17in x 42in |

18cm x 50cm x 122cm

7in x 20in x 48in |

|

|

Shipping dimensions (extrusions) |

10cm x 6cm x 154cm 4in x 2in x 61in |

17cm x 6cm x 154cm 7in x 2in x 61in |

N/A |

|

Shipping weight (total) |

23kg 51lb |

29kg 64lb |

18kg 40lb |

| US shipping | FREE |

||

| Worldwide shippingNEW! | FREE |

||

| Order | NEW! | NEW! | |

Genesis v1.7 |

Genesis XL v1.7 |

Express XL v1.1 |

|

| ORDER NOW | ORDER NOW | ORDER NOW | |

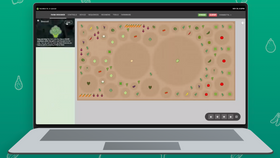

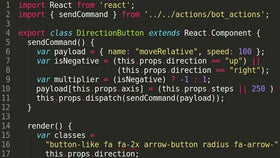

Software

You control and configure FarmBot using the free FarmBot web application at my.farm.bot. We expect to indefinitely offer free service adequate for home growing needs, though we may charge for commercial or industrial FarmBot usage, for FarmBots larger than 3m x 6m in area, for FarmBots growing large numbers of plants concurrently, for multi-bot/multi-user management, for advanced features, and/or for other increased account limits. You can always host the software on your own server if you do not want to use our service.

Warranty

We’re committed to providing you with the highest quality product. As we continue to develop FarmBot hardware and software, we will make changes. The final product that we ship to you may be different than the one shown in our videos, photos, documentation, and as described on our websites. If anything is damaged or defective, we will replace the parts free of charge within 30 days of delivery of the product. See our limited warranty for more information.

Support Policy

FarmBot requires basic computer and mechanical skills to install and operate. The majority of our customers do not require any technical support and are able to install FarmBot using the provided online materials. Initial setup will require several hours of configuration and learning to become completely operational. Please schedule adequate time to learn about the software and hardware systems.

While FarmBot is extremely customizable, we cannot provide support to customers that use unofficial parts or intend to use the device in ways it was not designed to operate. We provide limited troubleshooting and technical support for customers that require extra help with their installation. Free support is limited to 3 hours, is non-transferrable, and expires 24 months after purchase of a kit. Please read our full support policy for addditional details.

What you need to provide

Planter Bed

All FarmBots must be mounted to a raised bed or similar infrastructure. Neither materials for the bed nor soil are included with the kits because every installation will be different, and shipping lumber and soil would be prohibitively expensive.

Electricity

FarmBot must be plugged into a 110 or 220V outlet. The 30cm (1ft) power cord comes with a standard US 3-prong plug. You must connect this to your own extension cord if needed. Customers outside the US: you must provide a plug adapter if needed.

Water

FarmBot's water system has a 3/4″ female Garden Hose Thread (GHT) connection, meaning you can take a standard US garden hose and screw it into your FarmBot. You will need to provide a hose of the appropriate length.

Internet

FarmBot can only be controlled using the web app, so an internet connection is required. The Raspberry Pi has built-in WiFi, though you may need to reposition your WiFi router or install a repeater to ensure a reliable connection.

Planter Bed

All FarmBots must be mounted to a raised bed or similar infrastructure. Neither materials for the bed nor soil are included with the kits because every installation will be different, and shipping lumber and soil would be prohibitively expensive.

Electricity

FarmBot must be plugged into a 110 or 220V outlet. The 30cm (1ft) power cord comes with a standard US 3-prong plug. You must connect this to your own extension cord if needed. Customers outside the US: you must provide a plug adapter if needed.

Water

FarmBot's water system has a 3/4″ female Garden Hose Thread (GHT) connection, meaning you can take a standard US garden hose and screw it into your FarmBot. You will need to provide a hose of the appropriate length.

Internet

FarmBot can only be controlled using the web app, so an internet connection is required. The Raspberry Pi has built-in WiFi, though you may need to reposition your WiFi router or install a repeater to ensure a reliable connection.